ASM’s Atomic Playbook: Investor Day Maps €5.7bn Path on ALD, Epi and Services

ASM set a 2030 course—>€5.7bn revenue, 30% margins—built on ALD dominance, growing epi, outcome-based services and sustainability that lowers customers’ total costs.

ASM International used its Investor Day to make a clear case that the physics of ever-thinner films and ever-tighter features is turning into durable economics. The Dutch equipment maker sketched a 2030 destination of more than €5.7 billion in revenue, operating margins north of 30% and at least €1 billion in free cash flow, a plan that hinges on two pillars: staying indispensable at the atomic scale in deposition and turning its growing installed base into a higher-margin services engine.

The technical spine of the story is atomic layer deposition, where ASM says it now holds more than 55% of the single-wafer market and has doubled its installed base roughly every four years. That dominance survived—and benefited from—the industry’s step from FinFET to gate-all-around at two nanometers, a shift the company says validated earlier forecasts for a nodal jump in spending on ALD tools. Management expects the next step, from two nanometers to 1.4 nanometers, to add another $450 million to $500 million of available market at the node, reflecting both more layers and greater process complexity.

Epitaxy has become the second growth engine. ASM pegs its share in leading-edge epi at about 25%, up from 12% in 2020, with demand broadening from logic into DRAM as manufacturers move to denser cell architectures and begin putting peripheral transistors atop memory arrays. The company’s market framing is that both ALD and epi should outgrow the broader wafer-fab equipment market, with ALD reaching $5.1 billion to $6.1 billion and epi $2.5 billion to $3.2 billion by 2030—each implying high-single to low-teens compound growth.

If ALD is where ASM already leads, advanced packaging is where it wants to expand. As backend processes creep toward the front end, the company argues its chemistry and surface-engineering know-how translate into a bigger slice of that pie. By ASM’s tally, advanced packaging equipment could roughly double to $11.5 billion by 2030; today the firm sees itself playing in ALD, PECVD and surface prep that together represent about 15% of that market, with the ambition to push its serviceable share north of 30% by decade’s end.

Services—long a transactional business of selling parts and field time—are being recast as outcome-based contracts that guarantee tool availability and on-wafer performance. That shift has already shown up in the numbers: spares and service revenue doubled between 2020 and 2024, from €277 million to €547 million, helped by packages that promise uptime and tighter process control. Under the hood, ASM is leaning on dry cleaning, ALD-based protective coatings and automation that can place parts with micron-level precision—steps that extend component life, reduce defectivity and cut customers’ total cost of ownership.

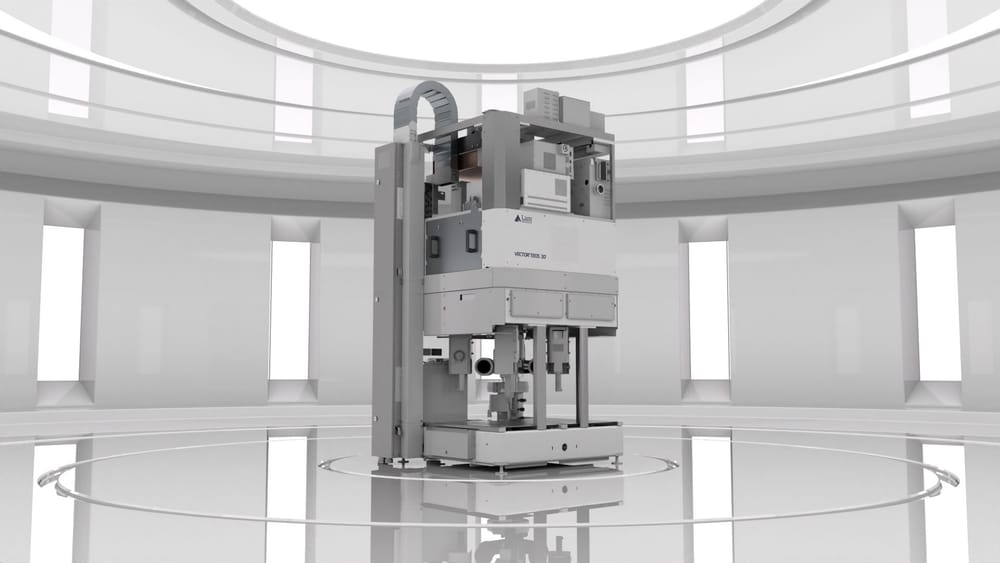

Behind the scenes, the firm is standardizing and hardening its platform. The flagship XP8 tool is being extended into the XP8e, a more modular base that can cluster surface cleans, selective etch and other steps needed for advanced ALD and CVD flows, including area-selective deposition now running at the two-nanometer node. The company is also pushing AI and machine learning deeper into both R&D and high-volume manufacturing, using anomaly detection to flag sensor-level drifts before they turn into scrap. Partnerships with IMEC, TU Eindhoven and the University of Helsinki are meant to keep the materials pipeline full.

At times, Investor Days can sound like wish lists. This one read more like a blueprint for compounding at the layer level—turning bigger stacks of ALD and epi into bigger stacks of cash. If chip making keeps marching into the angstrom era, ASM’s argument is straightforward: every new generation adds more places where only atomic precision will do.

Author

Investment manager, forged by many market cycles. Learned a lasting lesson: real wealth comes from owning businesses with enduring competitive advantages. At Qmoat.com I share my ideas.