China’s New Chip Toolmakers: Fast Followers, Deep Pockets, Narrow Gaps

China’s chip-equipment champions are moving from state-funded experiments to real contenders.

For years, the world’s chip factories were outfitted by a stable club of American, Japanese and Dutch firms. Walk the halls at SEMICON China today and the badges tell a different story. Beijing’s Naura now fills booth space with full suites of etch, deposition and furnace systems. Shanghai’s AMEC pitches high-selectivity etchers to memory makers. Clean and CMP tools wear logos from Hwatsing and ACM Research’s China arm. It is the physical manifestation of an industrial policy that has poured tens of billions into replacing foreign “black boxes” with domestic iron—and it is beginning to show up in the numbers. Naura, China’s largest toolmaker, guided 2024 revenue to roughly RMB 27.6–31.8 billion, up 25–44% year on year, while net profit rose even faster.

This surge is no accident. In May 2024 Beijing stood up Phase III of the National IC Industry Investment Fund—the “Big Fund”—with RMB 344 billion (about $47.5 billion) of fresh capital, explicitly prioritizing equipment and production inputs. Municipal funds, like Shanghai’s RMB 100 billion IC vehicle, add further lift. The money is designed to cushion domestic demand, back acquisitions and accelerate engineering roadmaps as U.S. controls tighten around advanced tools and techniques.

The market tailwind has been real. China accounted for about 40% of global wafer-fab equipment purchases in 2024, after a two-year binge of stockpiling and capacity adds. TechInsights expects a pullback in 2025—to roughly $38 billion of tool buys—as overcapacity bites and controls widen, but the center of gravity has shifted. Even after the step-down, SEMI still sees China leading front-end investment in 2025.

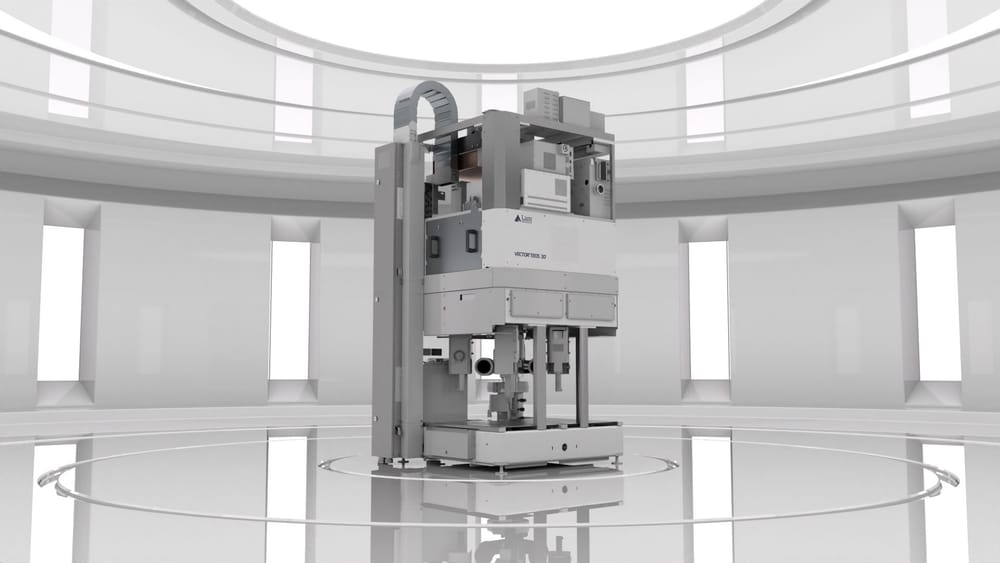

Inside the toolset, three product clusters show how quickly the locals have moved—and where the gaps remain. Start with etch and deposition, the largest buckets of spend in any fab. AMEC has built a genuine franchise in dielectric and conductor etch, winning slots in 3D NAND stacks where vertical channels demand high selectivity and uniformity. Industry press pegs first-half 2025 revenue up sharply on etch demand; more importantly, AMEC has been expanding into epitaxy and other adjacencies to deepen its wallet share at key customers. Meanwhile Naura—born of the merger of Sevenstar and North Micro—has broadened from vertical furnaces and PECVD into PVD, ALD and strip, and in 2025 even pushed into ion implantation through product expansion and deals. Piotech, rooted in thin-film deposition, has parlayed PECVD and ALD strength into new 3D-IC and advanced-packaging tools, including hybrid bonding equipment via its Piotech Jianke unit. The cumulative effect is measurable: Chinese suppliers lifted their share of global deposition markets to ~7% by 2024 from ~2% in 2019, with Naura gaining notably in PVD.

Cleaning and CMP tell a similar story. ACM Research’s China operations dominate single-wafer wet clean at local fabs and are guiding $850–$950 million of 2025 revenue as they scale their Tahoe platform and related wet benches. Hwatsing—born out of Tsinghua University CMP research—has become the domestic champion in polishers, posting strong 2024 profit growth and investing to push tool capability up-node. Policymakers like to quantify progress: one recent analytical survey credits Hwatsing as a driver of an eight-percentage-point share gain for Chinese CMP over five years, with dry etch and strip closing ground too.

Lithography is where the momentum meets physics. Photoresist coat-and-develop tracks—vital companions to scanners—are now supplied domestically by Kingsemi for 28-nanometer-class and above; Naura spent 2025 buying its way into Kingsemi to knit tracks tighter into its front-end suite. The scanner itself remains the bottleneck. Reports indicate SMIC is testing a homegrown immersion deep-UV tool developed by Shanghai Yuliangsheng, potentially viable for 28nm-class nodes with heavy multi-patterning. But even optimistic assessments suggest performance roughly akin to ASML’s 2008-era NXT:1950i, with production insertion not expected before 2027. EUV is out of reach for now.

Policy is reshaping the competitive chessboard. The U.S. widened its 2024–2025 controls beyond “bleeding edge” targets, layering on node-agnostic restrictions that can touch DUV multi-patterning and even some advanced packaging steps. Washington also keeps adding Chinese toolmakers and components suppliers to the Entity List. The immediate effect is twofold: Chinese fabs accelerate “local for local” purchases to de-risk future bans, and Chinese tool vendors redesign subsystems to purge U.S. content. That cocktail hurts foreign incumbents’ China revenue today and gives domestic makers a captive sandbox to prove themselves in mature nodes. It does not magically solve physics or precision engineering—but it buys time and volume.

The localization push has already produced showpiece lines. YMTC, China’s NAND champion, is running a trial line that uses almost half domestic tools, a milestone for a flow that still leans on foreign lithography and metrology. Analysts see ambitions to reach 150,000 wafer starts a month by 2026, but caution that yields on domestic tools lag imported gear and need seasoning. Even so, each incremental percentage point of localization locks in orders for Chinese vendors and chips away at the service and spares franchise of global rivals.

It’s not just organic growth; consolidation is part of the playbook. Naura’s creeping control of Kingsemi speaks to a broader state-encouraged rationalization—fewer, larger platforms to standardize interfaces, pool R&D and present a single throat to choke for top customers like SMIC, Hua Hong, CXMT and YMTC. Hwatsing has likewise absorbed assets to expand beyond CMP into thinning, scribing, cleaning and metrology. The goal: transform a patchwork of institute spin-offs into vertically integrated, customer-facing suppliers that can bid on turnkey modules rather than single tools.

Where are the limits? Start with metrology and inspection, the invisible nervous system of a fab. KLA and its peers still own e-beam and optical platforms that police defects and keep overlay in line. Ion implantation—dominated by Axcelis and Applied’s Varian line—has seen Chinese progress, including state-media-touted 28nm-class systems from CETC institutes, but breadth and field-proven reliability at high currents remain open questions. And while domestic DUV solutions inch forward, the step from a lab-qualified immersion scanner to a production-worthy fleet with world-class uptime, overlay and contamination control is a multiyear, multi-supplier slog. Reuters’ summary is blunt: even as Naura cracks the global top ten by sales, China’s weak spots remain lithography, testing and assembly gear.

Investors should also separate cyclical sugar highs from structural wins. After three years of outsized China buying, 2025 is shaping up as a digestion year, with overcapacity in mature nodes and a slower handset and appliance cycle trimming tool budgets. SEMI still models a modest up-year globally, powered by AI-led logic and memory expansions outside China, but Beijing’s checkbook will not be the only driver in 2026 and beyond. The best-positioned Chinese vendors—the Naura/AMEC/Piotech cluster in films and etch; Hwatsing/ACM in clean and CMP; Kingsemi in tracks—have the breadth and installed base to compound through the air pocket. The laggards will find life harder without the stockpiling bid.

Can the newcomers go global? ACM is trying, explicitly targeting the U.S. and allied markets with a localized supply chain and a broader product stack. Naura has begun to plant sales and service flags abroad. But geopolitics cuts both ways: any Chinese tool landing in an allied fab will invite scrutiny of its parts list and software pedigree, just as Chinese buyers increasingly ask multinationals to scrub U.S. content. The likeliest near-term battlegrounds are third-party foundries at 28nm and above, domestic memory expansions and advanced packaging flows where hybrid bonding and wafer-to-wafer stacks open fresh lanes for entrants.

The broader implication is that “decoupling by layer” is real. China is unlikely to close the EUV or leading e-beam gaps soon. It doesn’t have to. If domestic suppliers can reliably fill 60–80% of a mature-node bill of materials—and if customers can live with somewhat lower yields while they iterate—then a large swath of the world’s chips can be built with minimal exposure to allied export levers. That is an economic story as much as a technological one: relentless engineering, patient capital, and a home market big enough to learn in.

The club that outfits the world’s fabs is no longer closed. It is getting bigger, messier, more regional—and more political. Watch what ships into China’s 28-nanometer lines and 3D-NAND stacks over the next 24 months. That tool mix will tell you whether the domestic challengers are merely busy—or truly breaking through.

Author

Investment manager, forged by many market cycles. Learned a lasting lesson: real wealth comes from owning businesses with enduring competitive advantages. At Qmoat.com I share my ideas.