Where Chips Meet Chips: Besi’s Quiet Grip on the AI Packaging Boom

As transistor gains stall, hybrid bonding takes center stage. Dutch toolmaker Besi is turning precision and process lock-in into outsize margins—and a pivotal role in AI hardware.

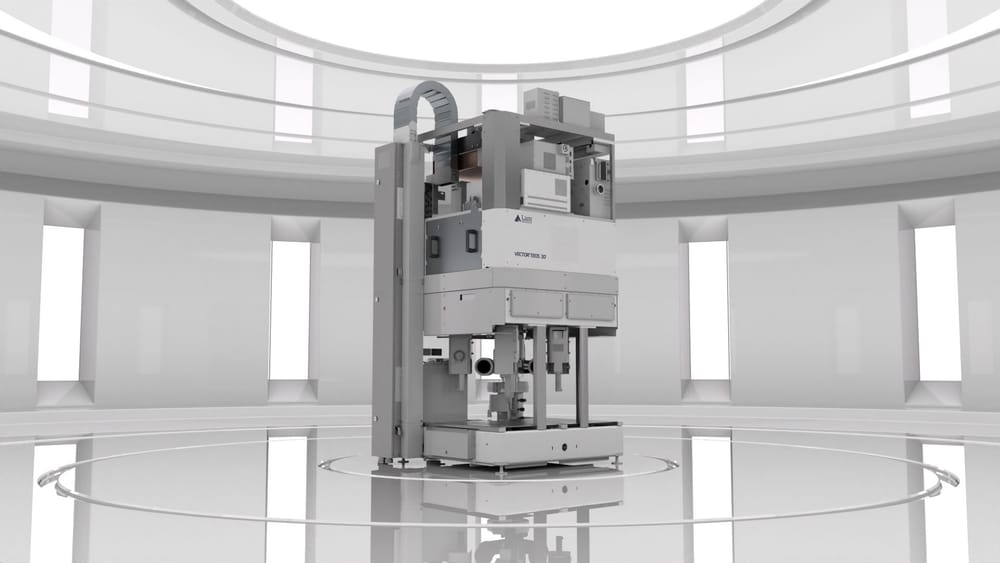

The hottest corner of chipmaking no longer lives at the bottom of a transistor. It sits where chips meet chips. That is where BE Semiconductor Industries—Besi, for short—has spent years sharpening a quiet edge. As the physics of shrinking transistors gets harder and more expensive, the industry is racing to stitch silicon together in three dimensions. The tool of choice for that job, hybrid bonding, has moved from R&D labs into high-volume lines. Besi, a Dutch specialist in die attach and advanced packaging, has become the name to beat in that niche—and it is starting to look less like a cyclical also-ran and more like a linchpin of the AI hardware boom.

That shift is visible in the company’s ambitions. At an investor day in June, Besi lifted its long-term revenue target by half, to €1.5 billion–€1.9 billion, and nudged expected gross margins up to a lofty 64%–68%, with operating margins of 40%–55%. Few capital-equipment makers in semiconductors talk in those ranges. Besi’s confidence rests on the idea that advanced chip stacking isn’t a sidecar to lithography and deposition—it is now core infrastructure for training and serving large AI models and for moving more data through ever tighter packages.

The endorsement that really turned heads arrived in April, when Applied Materials, the world’s largest semiconductor equipment vendor, disclosed a 9% stake in Besi. Applied framed it as a strategic, long-term investment; it did not ask for a board seat or signal a takeover. That nuance matters. If Applied thought it could simply build a rival bonder and squeeze Besi out, it probably wouldn’t be buying the stock. Instead, the move reads as a bet that hybrid bonding will sit alongside Applied’s process steps in tightly integrated flows—and that it’s faster to partner than to compete head-on.

Market structure supports the thesis. In its last full investor deck anchored on TechInsights data, Besi was credited with roughly 43% share of the die-attach market and an even bigger lead in advanced die placement—the sub-7-micron accuracy domain that underpins the finicky alignment hybrid bonding requires. Those aren’t commodity pockets; once a tool and process are qualified on a high-volume line, switching is slow and risky. The engineering and yield costs of a misstep are measured not in basis points but in ruined wafers and lost quarters.

The technology itself is deceptively simple to describe and maddeningly hard to perfect. Hybrid bonding presses two chips together face-to-face so that copper pads fuse while thin dielectric films intertwine, creating dense, low-resistance connections without the fat bumps of older approaches. At volume, placement accuracy has hit the 100-nanometer class, with roadmaps toward 50 nanometers as HBM stacks get taller and logic moves to even tighter pitches. Throughput and cleanliness are as consequential as accuracy; a few stray particles can turn an expensive wafer into scrap. This is the sort of edge Besi has cultivated across multiple product generations.

Demand is building, and not just in press releases. Orders tied to AI and advanced packaging began to outpace Besi’s sluggish mainstream businesses last year, even as automotive and China remained weak. The company has flagged a ramp in hybrid-bonding demand into the back half of 2025, citing new HBM iterations and advanced logic roadmaps that lean on 2.5D and 3D integration. TrendForce, which tracks memory closely, sees the same curve—more bonder buys ahead of HBM4 and next-wave AI accelerators in 2026–2027. If that cadence holds, this is less a one-off pop than a multi-year build-out.

The flip side is that Besi still lives with the industry’s usual indigestion. Early this year, it warned on sales as the recovery in its traditional segments lagged and Chinese demand stayed hesitant. That caution landed with a thud in the stock. Currency has also been unkind: a weaker dollar against the euro compressed gross margins in recent guidance. None of that changes the structural story, but it’s a reminder that even with a premium product line, Besi is not exempt from the stop-start rhythm of capex cycles.

Capacity is the tangible test of management’s conviction. Besi is doubling clean-room space in Malaysia to support the expected wave of hybrid-bonding systems and has stepped up R&D and process development in Southeast Asia. For a company of its size, expanding in lower-cost, high-skill locales is more than a margin play; it reduces lead times and supports closer collaboration with customers assembling in the region. As the tooling moves from bespoke installs to more standardized lines, time-to-qualify becomes an advantage of its own.

Competition is real. ASMPT, EV Group and Tokyo Electron all see green shoots in hybrid bonding and adjacent assembly flows. A homegrown Korean effort recently secured funding to develop bonder specs that would match the 100-nanometer class. Over time, standardization can compress performance gaps, and foundries and OSATs like second sources once yields stabilize. For now, though, Besi’s head start, installed base and the sheer difficulty of marrying accuracy, throughput and cleanliness keep the field narrower than many other equipment categories.

What makes Besi interesting isn’t just the product lead. It’s the economics. Even in choppy periods, Besi talks in mid-60s gross margins, and it is willing to pin its long-term colors to those masts. The math works when a tool sits in the middle of a flow that determines whether an HBM stack hits its bandwidth target or whether a chiplet-based CPU meets its power budget. When the value-at-risk is measured in the dollars per watt, the price of a bonder and service contract starts to look like insurance. Investors have noticed. Raising financial targets into a capex downcycle is not a common sport. Doing it with a major competitor on the share register is rarer still.

There are caveats. The hybrid-bonding narrative assumes AI workloads keep compounding, and that power and memory bottlenecks force architectures toward ever denser vertical stacks. If the industry finds alternative routes—say, more radical optical interconnects at the package level—some demand could shift. Customer concentration is another risk; a few big nodes at a handful of foundries and memory makers account for a disproportionate share of orders, and timing twists can swing a quarter. Besi also has to balance its profitable core in die attach with the faster-growing hybrid-bonding franchise without over-relying on one product hero. Those are high-class problems but problems nonetheless.

For now, the center of gravity in semiconductors is migrating from ever-smaller features to ever-tighter integration. Besi built its reputation in the mechanical-meets-metrology trenches where that change becomes real. If the company can maintain its precision lead and scale production without sacrificing yields, it will remain the quiet beneficiary of the AI arms race. In a sector obsessed with nanometers and teraflops, there is still room for an old-fashioned manufacturing truth: the company that helps everyone else go faster tends to do just fine.

Author

Investment manager, forged by many market cycles. Learned a lasting lesson: real wealth comes from owning businesses with enduring competitive advantages. At Qmoat.com I share my ideas.